- Ãëàâíàÿ

- Àâèàöèÿ è êîñìîíàâòèêà

- Àäìèíèñòðàòèâíîå ïðàâî

- Àêöèîíåðíîå ïðàâî

- Àíãëèéñêèé

- Àíòèêðèçèñíûé ìåíåäæìåíò

- Áèîãðàôèè

- Àâòîìîáèëüíîå õîçÿéñòâî

- Àâòîòðàíñïîðò

- Êóëüòóðà è èñêóññòâî

- Ìàðêåòèíã

- Ìåæäóíàðîäíîå ïóáëè÷íîå ïðàâî

- Ìåæäóíàðîäíîå ÷àñòíîå ïðàâî

- Ìåæäóíàðîäíûå îòíîøåíèÿ

- Ìåíåäæìåíò

- Ìåòàëëóðãèÿ

- Ìóíèöèïàëüíîå ïðàâî

- Íàëîãîîáëîæåíèå

- Îêêóëüòèçì è óôîëîãèÿ

- Ïåäàãîãèêà

- Ïîëèòîëîãèÿ

- Ïðàâî

- Ïðåäïðèíèìàòåëüñòâî

- Ïñèõîëîãèÿ

- Ðàäèîýëåêòðîíèêà

- Ðèòîðèêà

- Ñîöèîëîãèÿ

- Ñòàòèñòèêà

- Ñòðàõîâàíèå

- Ñòðîèòåëüñòâî

- Ñõåìîòåõíèêà

- Òàìîæåííàÿ ñèñòåìà

- Òåîðèÿ ãîñóäàðñòâà è ïðàâà

- Òåîðèÿ îðãàíèçàöèè

- Òåïëîòåõíèêà

- Òåõíîëîãèè

- Òîâàðîâåäåíèå

- Òðàíñïîðò

- Òðóäîâîå ïðàâî

- Òóðèçì

- Óãîëîâíîå ïðàâî è ïðîöåññ

- Óïðàâëåíèå

- Ñî÷èíåíèÿ ïî ëèòåðàòóðå è ðóññêîìó ÿçûêó

- Äðóãîå

Êóðñîâàÿ ðàáîòà: Planning of mobile complete set for a rural wind generatorÊóðñîâàÿ ðàáîòà: Planning of mobile complete set for a rural wind generatorPlanning of mobile complete set for a rural wind generator Abstract The aim of this thesis is to alleviate the chronic lack of electricity supply in the rural South African areas by designing a portable wind generator kit. An extensive assessment on the rural village of Ga-Rampuru, in Limpopo Province, was conducted, to investigate the present needs, as well as the availability of resources both human and material that would be needed to construct and assemble the system. From the inventory of recyclable materials found during the investigation the author was more inclined to suggest the design of a wind turbine that could be assembled and maintained by the local artisans. A two pole permanent magnet synchronous generator was designed using standard commercial magnets, which were later replaced by recyclable loudspeaker magnets that were found in the village. This was done to compare the output of the generator in both cases. All the designs were modelled in FEMM, a software package, to estimate the induced voltage and flux of the generators. Using standard commercial magnets the simulated voltage and flux levels were 9.4, 5.1, 3.6V and 0.0489, 0.0186, 0.0175 Wb, respectively. Assuming a generator current rating of 1 amp this would yield 36 watts at the estimated average wind speed of 4 meters per second. Then when these were substituted with recycled speaker magnets the generator yielded a voltage of 3.5V and a flux of 0.0171Wb. The estimated output power of the recycled generator was estimated to be 10.5W. This compared well with the power output from the commercial magnets generators. From these preliminary results it is quite apparent that a viable generator can be designed from the recyclable magnetic components. The same design procedure as outlined in this thesis can be used to design larger recycled generators with larger outputs. The design of this wind turbine will obviously have a wide range of positive developmental benefits on the community of Ga-Rampuru. The next stage was practical construction to validate of the simulation results. This however could not be realised in time. Chapter 1. Introduction 1.1 The subject of the reportThe aim of this thesis is to design a simple wind generator kit that can be easily assembled and installed by rural artisans. The kit will use recyclable materials that are found in the rural areas to ensure a cost effective and environmentally sustainable solution. 1.2 Background to research and investigation of rural electrification“Electricity brings immeasurable benefits to human life. With electricity, comes lighting and the ability to extend the daylight hours, to study and to improve education. With electricity come cooling and heating and the ability to store food and cooking. At its extended level, electricity facilitates communications, transportation and production and paves the way for the eradication of poverty, industrialisation and ultimately the growth of our country’s economy”.[3] Electricity is a basic necessity and access to it has a wide range of positive developmental benefits for communities [1], yet, in 2001 2.8 million South African households still had no access to electricity [2]. The majority of these households are poor and live in remote places which are located far from the central business districts and the country’s electricity grid. And this makes it very expensive to connect them to the country’s electricity grid. As a national initiative to improve the quality of life in South Africa, National Electrification Programme (NEP) aims to provide universal access to all South Africans by 2012 [4]. Hence, this has lead to the investigation of other safe, cost effective and environmentally friendly alternative methods of electrifying rural areas in South Africa. Renewable energy resources such as wind and solar, are the fastest growing alternative means of providing a reasonable amount of energy at the point of demand. The Government of South Africa is also determined that renewable resources will be a major complement to the national mix [4]. 1.2.1 Ga-Rampuru, a typical rural South African villageGa-Rampuru is a small village located in Limpopo Province in South Africa. The village is in a fairly rural mountainous area, which is situated some 58 odd kilometres from Polokwane, the provincial capital city. The area has sparsely populated households with some trading stores and schools. Most of the people in the village are unemployed and rely on agriculture for their subsistence. People in the village have to travel long distances to collect wood or to purchase fuels like liquid petroleum gas (LPG) and kerosene to meet their cooking, lighting, refrigeration, infotainment and other needs. Figure 1 illustrates a picture of an LPG refrigerator in one of the trading store in Ga-Rampuru. This picture and others that will follow in this thesis we taken by the author during a visit at Ga-Rampuru last June vacation. The supply of these fuels is both expensive and unpredictable. Additionally the problems related to the use of fuels such as kerosene are incidences concerning burned houses and respiratory problem for children who use kerosene candles for reading is well documented world wide [6]. The author paid a visit to the Provincial ESKOM office to enquire about any plans to extend the grid to Ga-Rampuru village; and the Electrification Manager guaranteed that ESKOM has plans to ultimately electrify the whole country by 2012. However, further discussions with people from Ga-Rampuru dismissed the ESKOM Manager’s promises as empty. They contended that they had heard similar promises but they still lived in darkness. It was the conclusion of the author that an alternative solution to the problem had to be devised. Some means of generating electric power to meet loads such as the refrigerator in figure 1, if only it could be an affordable design. The best design would clearly be one that uses local material and human resources. 1.2.2 Resource assessmentThe author spent the next three weeks exploring the resources available in Ga-Rampuru that would support the design and sustainable construction of electricity generators. To begin with Ga-Rampuru has two schools, namely Rampuru primary school and Seokeng secondary school, all which constitute a total population of roughly 1400 pupils. On average 30% of school leavers will continue to tertiary education, some will migrate to urban centres in search for jobs and a substantial number will remain in the village. This village is endowed with adequate human capacity with intermediate levels of education. These would constitute a source of trainable technicians and potential consumers of locally manufactured products. There are also local mechanics who fix cars and some electrical appliances. These people will be easily trained as they have hands on experience. Some of the people who left the village for jobs in the cities come back to settle down in the village and build big houses like the one indicated in Fig 2. This clearly indicates that this people can afford the electricity tariffs if they were to be supplied with power. Moving further around the village there was evidence of old windmills used for pumping water. Figure 3 shows one of the windmills. These windmills operate satisfactorily providing enough water to the villagers. The presence of these windmills in this area is evidence that there is some wind resource in the area. Further investigations took the author to various waste-dump sites and a range of disused old gadgets that could potentially be re-used, as shown in appendix A, were discovered. These included cables from an old car, loudspeaker magnets, drums and old machines that were used for grinding grain. The other natural resource in the area (of course) is the sun but from the inventory of recyclable materials found during the investigation it is more inclined to suggest the design of a wind turbine. 1.3 Objectives of the reportIn light of the above background, the main objective of this thesis is to design a small wind generator for Ga-Rampuru village using recyclable materials found in this village. The idea is to build an easily assembled and manufactured machine that can be build by the rural artisans. This wind generator must of course be cost effective. The resource assessment of Ga-Rampuru village is conducted in order to investigate the present needs, as well as the availability of resources both human and material that would be needed to construct and assemble the wind turbine using recyclable materials. Furthermore, the resource assessment analyses lead to an appropriate wind generator design specifically for Ga-Rampuru village. 1.4 Method of investigationThe investigations were conducted in July 2006 at Ga-Ramrupu village in Limpopo province. The author collected information regarding this village in the following manner: 1. The author grew up in Ga-Rampuru village and therefore knows the problems and challenges that the villagers face on a day-to-day basis living without electricity. This was an advantage in terms of moving around the village doing the resource assessment analysis. 2. One of the store owners in the village, Mr Morifi was interviewed regarding the issues he faces in supplying power to his store, especially to the refrigerator he has in store. The store owner mentioned that he has to refill the petroleum gas (LPG) in his store every two weeks. He also added that this is very expensive as there are also transport costs involved. 3. Face to face interviews were conducted with some of the villagers where many concerns and challenges were raised. Most of the villagers said that it has been several years since they have been promised to be electrified and nothing has been done to date. 4. The author paid a visit to the Provincial ESKOM office in Pretoria to enquire about any plans to extend the grid to Ga-Rampuru village. The ESKOM Electrification Manager, Jack Bandile was interviewed in this regard. 1.5 Plan of developmentThe report begins with a brief background of the thesis and introduction of the rural area for which the wind generator will be designed for. Then, the remaining project researches are outlined as follows: · Chapter 2 reviews the design of a small wind generator and after that a wind generator suitable for Ga-Rampuru village is designed using recyclable materials that where found in this village. · Chapter 3 details the procedure undertaken to design a permanent magnet synchronous generator for Ga-Rampuru village wind turbine. · Chapter 4, the generator geometry discussed in chapter 3 is modelled in FEMN using recyclable and commercial magnets to analyse and estimate both machine designs. · Chapter 5 discusses the results found in chapter 4. · Chapter 6 details all the steps that were taken in an attempt to assemble a prototype of the wind generator. · Chapter 7 & 8 concludes the discussion based on the analyses and finally presents recommendations. Chapter 2. Design of the wind turbine prototype 2.1 Background on wind energyWind powered systems have been widely used since the tenth century for water pumping, grinding grain and other low power applications [9]. Since then, this has lead to an investigation and attempt to build large wind energy systems to generate electricity. Wind energy has proven to be cost effective and reliable in the past years. The main development of this technology has been with large wind turbines in the industrialized world, but there is scope to deliver decentralized energy service in the rural areas of developing countries [6]. Furthermore, wind energy is an attractive option to generate electricity since it does not consume fossil fuels nor emit greenhouse gases. The land on which the wind generators are build may also be used for agricultural purposes such as ploughing the land or domestic animal gazing. During its transition from the earlier day’s wind ‘mills’ to the modern electric generators, the wind energy conversion systems (WECS) have transformed to various sizes, shapes and designs, to suit the applications for which they are intended for [5]. In this chapter, the main components of a simple small wind generator will be investigated and a wind generator suitable for Ga-Rampuru village will be designed using recyclable materials found in the area. The available wind resource is governed by the climatology of the region concerned and has a large variability from one location to the other and also from season to season at any fixed location [9]. Hence, it is important that the wind generator is designed for a specific area; this will ensure that the wind energy in that specific area is exploited to generate maximum power from the wind. 2.2 Wind turbine basic principlesThe wind generators are specially designed and build to extract power from turning blades with the maximum efficiency and minimum complexity [6]. The magnet rotor disk rotates as a result of the force of the wind on the turbine’s blades. A typical small wind generator consisting of blades, tower, PM generator and the cabling is illustrated in figure 2.1. The main components, which are common to most wind generators, will be discussed below.

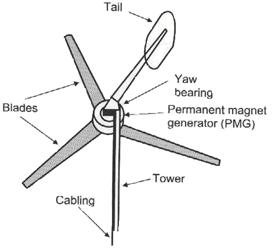

Fig 2.1 Basic features of a typical small wind generator [6] 2.2.1 The bladesModern wind turbine rotors usually have two or three wooden blades. A larger number of blades would create more turning force (torque), but would not be capable of driving the PM generator fast enough to generate the required voltage, because the rotor would turn more slowly [6]. The rotor blades are designed in such a way that they extract the maximum power from the wind. Power supplied by the blades to the generator is [7]:

where In equation 2.1 above, the power drawn from the wind is proportional to the cube of the wind speed. This means that if the wind speed doubles, there is 8 times as much power available from it [7]. A further important parameter is the tip speed ratio. The tip speed ratio is defined as the ratio of the tip of the blade to that of the undisturbed wind velocity entering the blades [11]. The ratio is given by [7]:

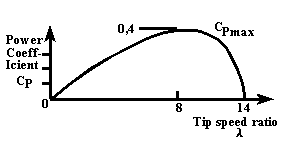

where R is the radius of the blades, ωr is the rotor speed in rad/s and W the wind speed (m/s). Multi bladed rotors operate at low tip speed ratios of 1 or 2, where else, one, two or three bladed rotors operate at higher tip speeds of 6 to 10. The power coefficient in equation 2.1 depends on tip speed ratio as shown in figure 2.2. For a particular wind rotor design there exists a tip speed ratio which will produce the maximum value of power coefficient [11].

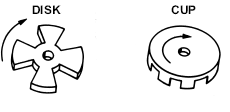

Fig. 2.2 Power coefficient Cp versus tip speed ratio [11] 2.2.2 Permanent magnet generatorUsing permanent-magnet generators for small wind turbines is very commonly used world wide. Usually an AC generator with many poles operates between 10-100 Hz. Many configurations use surface mounted three phase permanent magnet synchronous generators with a rectifier connected to the generator terminals. [16] A simple PM generator consists of the stator, magnet rotor disk and a shaft. The magnet rotor disk is mounted on a bearing hub so that it can rotate on the shaft due to the rotating blades of the wind generator. The stator has coils of copper wire wound around them, which are accommodated in the slots. Electricity is then generated when the magnets on the rotor disks rotate past the coils embedded in the stator. The magnetic field that is created induces a voltage in the coils [6]. 2.2.3 Rotor designThere are two types of rotor configurations commonly used world wide, these are the disk and the cup as shown in figure 2.3 below [20].

Fig. 2.3 Disk and cup rotor designs The radius of the rotor primarily depends on the power expected from the turbine and the strength of the wind regime in which it operates [5]. 2.2.4 TowerThe main function of the tower is to raise the blades and the generator to a height where the wind is stronger and smoother than the ground level. The wind speed increases with height because of the earth surface [9]. The tower should be high enough to avoid any obstacles such as trees, building, etc. Practical considerations such as expense, safety and maintenance limit the tower to between 10m to 20m [6] above ground level. 2.3 Design of a wind turbine for Ga-Rampuru villageIn this section a wind generator that is designed specifically for Ga-Rampuru village will be discussed. The generator will be designed using recyclable materials such as car brake plates, cables and drums found in the village [See appendix A]; this will clearly ensure a cost effective design. The wind turbine will be designed in such a way that the local people can easily assemble and manufacture it themselves. All the recyclable materials that will be used in this design will be discussed below and an artist impression of the wind generator will be sketched. 2.3.1 The drumThe output of the wind generator depend on the amount of wind swept by the blades, therefore the wind extracting materials in a wind generator are very significant. A plastic drum will be used in this design to extract the wind since it can be easily shaped and carefully balanced to run smoothly. Also, it is resistant to fatigue braking and has a very light weight. The drum will be assembled as follows: 1. The top and the bottom part of the drum will be cut carefully by using a knife or pair of scissors to make a cylinder with open ends. 2. The cylindrical drum is then cut length-wise into two equal halves. 3. The two halves are then glued together similar to the drum shown in figure 2.4.

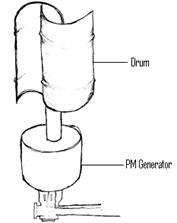

Figure 2.4 An S-shaped drum To prevent the over speeding of the drum, the permanent magnet generator should always be connected to a battery or other electrical load. If this is not done the wind turbine will become noisy and may vibrate so much that some parts come loose and fall to the ground [6]. 2.3.2 Magnet rotor diskAfter a tour around the village neighbourhood dumpsites it was discovered that there are many discarded loud-speakers that are no longer in use in the village. These loud-speakers have permanents mounted to their back. Since the PM generator requires magnets, these loud-speakers will be recycled and the magnets on them will be used in this design. Figure 2.5 shows one such magnet that was found in the village. There are many factors such as heat, radiation and strong electrical currents that can affect the strength of a magnet [8], especially in such discarded state. These factors will be discussed later to investigate exactly how much surface magnetic flux density these magnets loose in the dumpsites. And later on in this thesis the performance of a PM wind generator designed using standard commercial magnets will be compared to a generator using the recycled loudspeaker magnets as substitutes. Designing a generator using the speaker magnets will pose the following challenges due to their shape and strength: · How does one design a machine with these magnets? · Do they have to be smashed and aligned to work? · Or should they be used the way they are? · How much flux density do these magnets have, in other word, can they give out any power when used in the generator design? · Can different magnet types be used on one machine? As this magnets are picked randomly in the rural area. 2.3.3 Rotor DiskA cylindrically shaped rotor is preferred as it allows the proper distribution of flux over the armature surface as the field coils are spread over the periphery of the cylindrical rotor. Hence, a brake plate from an old car like the one in figure 2.6 will be used as the rotor in this design to hold and house the magnets. 2.3.4 Distribution cablesAll the cabling that will be required in the construction of the wind generator was found in an old car in the village [See figure 2.7]. 2.3.5 Artist impression of the wind turbineFigure 2.8 below shows the artist impression of the wind generator designed exclusively for Ga-Rampuru village.

Figure 2.8 Ga-Rampuru wind generator The following chapters describe the steps taken by the author to investigate the performance of a synchronous permanent magnet machine constructed using recyclable loudspeaker magnets. Chapter 3. Generator Design 3.1 A brief backgroundThis chapter will detail a simple procedure undertaken to design the wind generator from recyclable materials. Permanent magnet machines are preferred for this application as they reduce the excitation losses significantly and hence a substantial increase in the efficiency of the machine. In addition, permanent magnet machines are simple to construct and maintain [10]. The most common wind turbine systems are three blades rotating on a horizontal axis coupled to an alternator to generate electricity, which could be used to for battery charging. For a picture of a typical basic wind turbine system refer to figure 2.1 in chapter 2. A normal two- pole synchronous permanent magnet generator will be designed and its performance will be analysed. Then recyclable loudspeaker magnets found in the rural area of Ga-Rampuru village will be used to substitute the standard commercial magnets in the generator. The performance of the new generator will be analysed to understand the effect of the loudspeaker magnets on the generator performance. For this investigation, matching the refrigerator load in chapter 1 will not be a priority. This chapter will start with outlining the desired generator specification and then the generator will be designed thereafter. To design the generator the permanent magnet properties will be discussed to understand their effect on the generator performance and losses due to these magnetic materials will also be investigated. And then, all the variables that are necessary to construct and design a generator geometry will also be discussed. Throughout this thesis the generator performance will be tested under no-load conditions. 3.2 Generator specificationsIn this thesis, a generator with the following specifications will be designed and modelled in FEMM, a finite element package: · Output power = 36W @ 12V · Number of phases = 3 · Number of poles = 2 The choice of the above dimensions of the generator was influenced by the following consideration: ·Induced output voltage, 12V is standard voltage that is used in many applications. For example it is suitable to charge a battery. Batteries are suitable to power a wide range of rural appliances and instruments especially in remote areas of South Africa [11]. ·The generator must be easily assembled and manufactured so that the rural artisans with little training can be able to assemble this generator. The following design procedure will be followed: 1. A simple two-pole synchronous permanent magnet generator will be designed using available standard commercial magnets such as ceramics, alnicos and rare-earth magnets. 2. The effects of the above magnets on the performance of the generator will be investigated. 3. The magnets from a loudspeaker that was randomly picked in the village will then be used in the design and the performance will also be investigated. The designs above will be modelled using FEMM, a finite element package. The main reason for using FEMM is to observe the output induced voltage of the generator. This will be the method of how the performance of the generator will be monitored. 3.3 Generator basic principleThe main function of a generator is to supply power to the load, in order to do so; voltage has to be generated at the terminals. The generator principle is based on Faraday’s law of induction [10]:

where

e is the instantaneous voltage, The

law states that for voltage to be induced in a winding, the magnetic flux has

to change relative to the winding. This means that the flux linkage is changing

and the conductor is fixed or stationary. The flux linkage is the total flux,

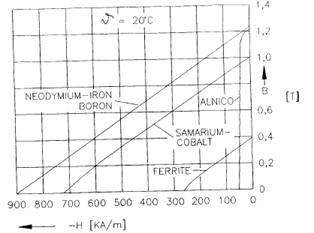

To generate voltage in practice, a mechanical motion and a source of magnetic flux must be present. The mechanical motion can be linear or rotational, in this thesis the motion is rotational and provided by the wind turbine. The source of flux is permanent magnets. 3.4 Properties of permanent magnetsThe use of permanent magnets in the construction of electrical machines has lots of benefits. A PM can produce magnetic flux in the airgap with no exciting winding and no dissipation of electric power [14]. Permanent magnets are known for their large hysteresis loop and B-H curves. These curves are in the second quadrant of the loop called the demagnetization curve; this is where the magnets operate. Demagnetization curves of the PM materials are given is Fig 3.1 In all machines using permanent magnets to set up the required magnetic flux, it is desirable that the material used for permanent magnets have the following characteristics [12]: a) A large retentivity (residual flux density) so that the magnet is “strong” and provides the needed flux b) A large coercivity so that it cannot be easily demagnetized by armature reaction fields and temperature. For analysis purpose, the magnet properties have to be known, the remanence flux density Br and coercivity Hc. The magnets are characterised by a large B-H loop, high Br and Hc. Table 3.1 summarizes the properties of some of the standard commercial magnets, these were estimated from figure 3.2 which indicate the demagnetization curves of different permanent magnet materials.

Table 3.1 Magnets properties

Figure 3.1 Demagnetization curves for different PM materials The remanence magnetic flux density Br is the magnetic flux density corresponding to zero magnetic field intensity. High remanence means that the magnet can support higher magnetic flux density in the airgap of the magnetic circuit. While the coercivity Hc is the value of demagnetizing field intensity necessary to bring the magnetic flux density to zero in a material that is previously magnetized. High coercivity means that a thinner magnet can be used to withstand the demagnetization field [10]. 3.4.1 Types of magnetsThere are three main types of magnets that can be found, these are [10]: 1. ALNICO (Aluminium, nickel, cobalt, etc.) These type of magnets poses high magnetic remanent flux density and low temperature coefficients. The coercive force is very low and the demagnetization curve is extremely non-linear. Therefore, it is very easy to magnetize and demagnetize ALNICO magnets. 2. Ceramic or Ferrites (BaFe203 or SrFe203) A ferrite has a higher coercive force than Alnico, but at the same time has a lower remanent magnetic flux density. Their main advantage is their low cost and very high electric resistance. 3. Rare – earth (SmCO, NdFeb-Neodynium Iron Boron) These are one of the strongest types of magnets available. They poses high remanent flux density, high coercive force, high energy product, linear demagnetization curve and low temperature coefficients. The main disadvantage is the cost. High performance rare-earth magnets have successfully replaced Alnico and Ferrites magnets in all applications where the high power-to-weight ratio, improved dynamic performance or higher efficiency are of prime interest. 3.4.2 Factors affecting recycled magnetsThe recycled magnets that will be used in this thesis were randomly picked; therefore there is no indication on how long they have been in the dumpsites. The following are the factors that can affect the strength of magnets: · Heat · Radiation · Other magnets in close proximity to the magnet If a magnet is stored away from high temperatures, and from the factors mentioned above, it will retain its magnetism essentially forever. Modern magnet materials lose a fraction of their magnetism over time if affected by the above factors [8]. 3.5 Generator lossesThe losses in a synchronous generator consist of rotational loss (mechanical loss and magnetic loss) and copper loss in the armature winding. The rotational loss and the field winding loss are subtracted from the power to obtain the power developed by the armature. By subtracting the copper losses in the armature from the developed power, we obtain the output power of a synchronous generator. In this section, the core loss will be discussed since they are due to the magnetic flux variations. 3.5.1 Eddy current lossThis power loss occurs in a magnetic core when the flux density changes rapidly in the core. Because core material has resistance, a power loss i2R will be caused by the eddy current and will appear as heat in the core [13]. The average eddy current loss is:

where Pe is the eddy current loss in watts (W), ke is the constant that depends on the conductivity of the magnetic material, f is the frequency in hertz (Hz), δ is the lamination thickness in meters, Bm is the maximum flux density in tesla (T) and V is the volume of the magnetic material in cubic meters (m3) [14]. The eddy current losses can be reduced by [13]: · Using a high-resistivity core material · Using a laminated core, in transformers and electric machines the parts that are made of magnetic core and carry time-varying flux are normally laminated. 3.5.2 Hysteresis lossDuring a cycle variation of current i, there is a net energy flowing from the source to the coil-core assembly. This energy loss goes to heat the core. The loss of power loss in the core owing to hysteresis effects is called hysterisis loss. By testing various ferromagnetic materials, Charles Steinmetz proposed that hysteresis loss can be expressed as [14]:

where Ph is the hysteresis loss in watts, kh is a constant that depends upon the magnetic material and n is the Steinmetz exponent. 3.5.3 Core lossThe hysterisis loss and eddy current loss are lumped together as the core loss of the coil-core assembly, and given by:

3.6 Design VariablesIn the following section, all the parameters that are necessary to design and construct a generator will be discussed and variables such as generator diameter, length, etc. will also be calculated. 3.6.1 Speed of the generatorThe annual mean wind speed at Ga-Rampuru is approximately 4m/s [11]. The rotor will rotate at the same speed as the wind turbine; therefore this means that the rotor will rotate at:

The rotor speed and the average frequency of the induced voltage are related by:

Since a two-pole machine will be designed, the frequency is calculated using equation 3.9 to be 39.79 Hz. 3.6.2 Rotor and Stator CoreA cylindrically shaped rotor will be appropriate for this design as it allows maximum flux distribution over the armature surface as the field coils are spread over the periphery of the rotor. This type of design also accommodates the use of small cylindrical magnets [11]. A low carbon steel core with low permeability will be used in this design as it was found in the recyclable materials found in the village. This type of steel is cheap and mostly available. Compared with other better and expensive steel such as silicon, cobalt, etc. this type of steel has a very high core loss. The steel saturation flux density Bsat is estimated from the BH curve to be 1.5T. 3.6.3 Rotor Diameter (D)The rotor diameter must be greater than the rotor yoke height (Hry), shaft radius (Rshaft) and the radial magnet length (Lm) [10]. D = 2 Hry + 2 Rshaft + 2Lm (Eq. 3.8) In this design, D is restricted by the magnet arc radius of 25mm. Therefore D will be 50mm. 3.6.4 Rotor and Stator Yoke heightsThe minimum rotor yoke height Hry is the same as the stator yoke height Hsy. The height should be large enough to avoid saturation. This also has advantages of reducing core loss and reluctance. The minimum yoke heights are given by [10]:

3.6.5 Airgap LengthThe airgap length has a minimum value limited by the manufacturing tolerances; this value is typically in the range of 0.3mm to 1mm. In this design 0.5mm is chosen to be the airgap length. 3.6.6 Generator LengthThe generator length is estimated to be 95mm; this is approximated from flux required to give the output voltage of the generator. 3.6.7 Airgap Flux Per PoleIn a radial machine, the flux per pole is given by:

where B is the average airgap flux density, D is the rotor inner diameter, L is the generator length, Kst is the lamination stacking factor and p is the pole pairs. For this design the average flux density per pole Bgav is equal to the peak flux density Bg since the magnet arc is close to 180 degrees. Therefore the peak airgap flux is estimated to be 0.5T at the airgap and Kst is assumed to be 0.97. The airgap flux and the lamination stacking factors were estimated from the following dimensions of the loudspeaker magnet: · Magnet arc = 180 mechanical degrees · Inner radius = 8mm · Arc radius = 25mm · Magnet radial length = 4mm · Area of one pole = 706.8 μm2 From the above magnet dimensions, the flux per pole in the machine is then estimated to be 1.16 mWb this value is calculated from equation 3.10. 3.6.8 WindingsThe stators of most synchronous generators are wound with three distinct and independent windings to generate three-phase power [14]. A simple layer winding was used in this design. Slot per pole per phase was chosen to be 1 and the winding pitch was full pitch. A. Types of winding The preferred type of winding is distributed winding as it reduces harmonics and makes better use of the stator or rotor structure. The mmf induced in the airgap is not sinusoidal, to get a pure sinusoidal mmf the number of slots have to be infinity. This means that the distributed winding is expected to have some harmonics. Induced voltage for the distributed windings is:

Kw is the winding factor and depends on the winding arrangements and has a value less than unity. Distribution factor Kd and a short pitch factor Kp reduces the winding voltage magnitudes but also reduces certain harmonics in EMF and MMF waveforms.

Distributed winding configuration has one slot per pole per phase and its winding factor is equal to 1. B. Winding arrangement Single layer winding, where each slot contains one coil side, will be used in this design as it is economical to manufacture and has simpler end connection. Emf and mmf can be modified to reduce harmonics. In a three phase system even harmonics do not appear due to the winding symmetry, the only visible harmonics are the belt harmonics. C. Winding Pitch Short pitch is the most commonly used type of winding pitch. It reduces the distorting harmonics and produces a truer sinusoidal wave. The length of the end connection is also reduced thereby saving copper and reducing copper loss in the coil. The drawback of short pitch winding is that the induced emf in it is smaller than in a full-pitch coil. The reason is that the total flux linking the short-pitch coil is smaller than that of the full-pitch coil. 3.6.9 Number of turnsThe number of turns per pole is estimated to be 60 turns from equation 3.11. The design parameters discussed will be modelled in FEMM in the next chapter to induce the output voltage and flux of the generator. Chapter 4. Modelling the design in FEMM 4.1 IntroductionThe investigation that will follow focuses on the effect of substituting standard commercial magnets with recyclable speaker magnets that were collected from a dumpsite in the village, to compare the performance of the generator in either case. In this chapter, the two pole generator geometry discussed in chapter 3 will be modelled in FEMM to analyse the output induced voltage and the flux of the generator. The lua-script in FEMM is run and the rotor is rotated 360 electrical degrees, for the lua-script refer to appendix C1. Initially, a choice was made of three typical commercial magnet grades. Neodymium-iron-boron NdFeB was chosen from the rare-earth magnet group. Alnico6 was chosen from the Alnicos and the last type was barium ferrite from the ferrite or ceramic group. Then the machine will be modelled using different types of commercial magnets to investigate the performance of the generator. The author then proceeded to investigate the magnetic properties of the loudspeaker magnet. This was done so that the parameters can be modelled in the finite element package. Finally a design using the loudspeaker magnets was modelled to explore the recycled generator output. 4.2 Two pole geometryTable 4.1 below summarizes the generator specifications that were discussed in chapter 3. These parameters will be modelled in FEMM to view the output induced rms voltage and the flux.

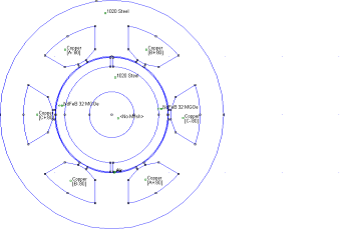

Table 4.1 Data of designed PM machine The design is modelled in FEMM and is illustrated in figure 4.1 below.

Figure 4.1 The generator modelled in FEMM 4.3 Commercial magnetsTo investigate the performance of the generator, the author began by modelling the generator with standard commercial magnets with the properties given in table 3.1. The output rms emf and flux of the generator is tabulated in table 4.2 with different magnets that were used in the design. Refer to appendix B for the graphs of the outputs. Matlab soft ware was used to draw the output rms emf and the flux, matlab code included in appendix C2. Table 4.2 Generator output with commercial magnets

4.4 Recyclable magnet found in the rural areaThe magnet that was used in this section was from a loudspeaker that was found lying in one of the dumps at Ga-Rampuru village. To start with the magnet shape was not of concern. The author aimed to investigate the performance of the magnet on the speaker if used as it was found. The properties of this magnet were investigated and a design was modelled using these magnets. The magnet is shown below in figure 4.2. 4.4.1 Background on the characteristics of loudspeaker magnetsFor speaker applications, the amount of permanent magnet required is directly proportional to the rated output power of the speaker. In other words high power speakers are often made using the high-grade magnetic types like the rare-earth. But since the speakers found in the dumpsite were from low power appliances their typical magnets are normally from the ceramic group type. In addition unlike Alnico magnets, ferrite or ceramic magnets are not easily demagnetised magnetized and hence find wide application in such appliances. 4.4.2 Properties of the loudspeaker magnet According to its nameplate the speaker that used the magnet in figure 4.3 had a 0.5W rms and an impedance of 8 ohm. The magnet type on the loudspeaker is a ferrite [Refer to appendix D1]. The manufacturer of the magnet on the speaker is traced in order to find the B-H properties of the magnet on the speaker. Appendix D2 indicates TDK datasheet for ferrite magnets FB series. These notes were used to find the magnetic, physical and mechanical characteristics of the magnet. The properties of the loudspeaker are summarized in table 4.3.

Table 4.3 Summarized properties of the magnet speaker 4.4.3 Output EMF and flux of the recyclable generatorThe properties were modelled in FEMM, and the generator outputs are tabulated in table 4.4. Refer to appendix B2 for the graphs of the outputs.

Table 4.4 Generator output with the loudspeaker magnet4.5 The estimated output power of the generatorsThe output electrical power of a generator is given by:

where V is the terminal voltage of the machine. The power factor is assumed to be unity for these calculations since all the simulations and investigations are done at no-load. From the rated power of the generator which is 36W. If the rated voltage is assumed to be 12 V then the rated current of the generator can be calculated from equation 4.1 to be 1A. Table 4.2 and 4.3 above gives the results of the simulated induced voltages and flux obtained from the generator with commercial and recycled magnets. Using the 1A above as the rated current, the output power of the generator using commercial magnets and recycled loudspeaker magnets is summarized in table 4.5 below. The output power in all the cases is calculated from equation 4.1.

Table 4.5 The output power of the generator Chapter 5. Analysis of the generator outputs In this chapter the author first began by analysing the output power of the generator designed with commercial magnets and the one with recycled loudspeaker magnets. The author then explored the factors that may have affected the outputs from the recycled generator. The terminal voltage induced from the recycled generator is also explored to view if it can be used in any applications in the rural village. This is done so that the voltage can be evaluated if it is useful or not Lastly the loudspeaker magnets are investigated to view how they can be used in the recycled generator design; whether they should be smashed and aligned to be re-used in the generator design or if they should be used the way they are without being smashed. 5.1 The estimated output power of the generatorsThe output power of the generators is estimated from the output induced voltages of the generators. Consequently, this means that the higher the terminal voltage of the generator the larger the output power. From the theory of magnets it is clear that the induced voltage is directly proportional to the remanent magnetic flux density Br of a magnet. In other words it is expected that rare-earth magnets which posses higher Br will always induce high voltage when used in generators. Therefore it can be said that the type of magnet used in a generator is very important as it determines the output power of the generator. As can be seen from the results, the induced voltage of the generator with NdFeB magnets from the rare-earth magnet family is higher than that with the AlNiCo and ferrite magnets. This was expected because of the different B-H properties of these magnets. The recycled generator in this thesis was designed using loudspeaker magnet that is from the ferrite family. These types of magnets are cheap and readily available, but their disadvantage is that they posses low surface flux density. The induced voltage was therefore expected to be much lower than the voltage induced in a generator with NdFeD magnets. 5.2 The rms output flux of the generatorThe magnetic flux density in the gap of PM generators is limited by the remanent magnetic flux density of PMs and saturation magnetic flux density of ferromagnetic core. Hence, the simulated value of output flux is directly proportional to the remanent magnetic flux. In addition, permanent magnet machine cannot normally produce the high flux density of a wound pole rotor. 5.3 Factors that may have affected the recycled generator outputsThere are many factors that should be taken in consideration with regards to the induced voltage from the recycled generator. Some magnetic deterioration may have occurred after the magnets were thrown into the dump. But, due to the magnet’s magnetic permanent properties, these magnets are expected to still have some surface flux density when found in the dumpsites. This is evidence that any permanent magnet that is found in the dumpsites can be reused in a generator design to induce some voltage, of course depending on their B-H properties. The estimated properties of the speaker magnets that were used in this thesis were found from the loudspeaker manufacture, clearly these properties will not be the same as the properties of recycled magnets that were found in the rural area of Ga-Rampuru. These recycled magnets have been affected by different conditions such as temperatures, climates, etc. The exact properties of the recycled magnets can only be found by testing these magnets in the laboratory. For this thesis the author was unable to take the loudspeaker magnets found in the rural area of Ga-Rampuru to the laboratory. 5.4 Applications of voltage from the wind turbineThe induced voltage of the generator will vary with the wind speeds experienced in this village. The generator can be connected to a battery to store the power which can be utilized when there is little or no wind. If more power is required, the voltage can be boosted by using any economical booster that can convert the output of the recycled generator to at least a minimum of 12V. The voltage from the booster can then be put through a cheap electronic regulator that will only charge the battery if the boosted voltage from the wind generator is sufficient to produce at least 12V direct current. To power the refrigerator in chapter 1, the store owner in the village will have to purchase an inverter that will convert the DC voltage to AC voltage. The inverter will convert the low-voltage from the battery (12V) into mains-type 230V alternating current. 5.5 Design using speaker magnetsFinally, the author investigated how speaker magnets can be used in the generator design, if they have to be smashed or used as they are. As already investigated, loudspeaker magnets are commonly from the ferrite magnets family. Ferrite and rare-earth magnets are by nature very hard and brittle. Although they can be cut, drilled and machined this should only be done by individuals who are experienced with ceramics. If the magnets get over about 300 deg F, they will lose their magnetism permanently [17]. Therefore, it will be very difficult for rural artisans to cut these magnets and use them. Due to limited time the author could not investigate if these magnets can be used as they are in the machine. In the next chapter the author attempts to assemble the wind generator in the laboratory. Chapter 6. Practical comparison of the generators 6.1 IntroductionThe following chapter outlines the steps that were taken in order to assemble the permanent magnet generator discussed in the previous chapters. This is done in order to compare the practical outputs of the generator with the simulated ones. The other reason is to investigate the performance of recyclable magnets with irregular shapes. This investigation will only concentrate on assembling the generator part of the wind turbine system. For the construction of the PM generator in this thesis two options were considered, the first was to collect readily available off-shelf materials to assemble a small generator. And the second was to convert an AC induction motor to a PM generator. Both options are discussed in this chapter. 6.2 Materials required to assemble a PM generatorThe main idea is to build a portable generator that is easily assembled and constructed in the laboratory. The author first begins with highlighting all the materials that are needed in the construction of this generator. Figure 6.1 gives the schematic of how the generator will look like.

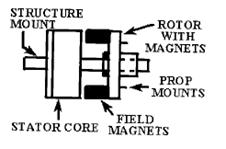

Figure 6.1 Basic wind generator design From the generator illustrated above it is clear that the following materials will be required in the construction of the generator: · Magnets · Stator and rotor · Rotor mounted on a rotating structure · Structure mound In the following sections the author will outline steps taken and the challenges faced in collecting these materials. 6.2.1 Magnets used in the generatorIn the investigation of the performance of the generator, the author was to begin by designing the generator using standard commercial magnets, which were to be later substituted with recyclable magnets. The recyclable magnets are picked randomly in the dumpsites of Ga-Rampuru village. Finding commercial magnets for this investigation was a major challenge since for this two-pole generator the author needed to purchase two NdFeb32 magnets, two Alnico5 magnets and two ceramic8 magnets. 6.2.2 Stator and rotorThe rotor rotates with the structure mount while the stator is fixed and mounted to a support structure. Since all these investigations were to be carried out under controlled laboratory conditions a drive and a frequency inverter which are readily available in the laboratory will be used to rotate the rotor at the desired speeds. The drive will rotate the rotor and the induced voltage from the coils on the stator will be monitored by a voltmeter in the laboratory. Figure 6.2 illustrated this type of drive. The size of the rotor in this thesis was constrained by the diameter of the recyclable speaker magnets. Therefore steel with this shape had to be found or cut to this shape. After finding the relevant steel, the cylindrical steel has to be drilled at the center. 6.3 Converting an induction motor into a PM generatorDue to the challenges faced in gathering the materials needed to assemble the generator the author then decided to find an alternative method to investigate the performance of the generator using recyclable magnets. A company called Magnetag that supplies motors and generators was approached and after some negotiations the company was willing to donate an AC induction motor to the author. The idea was to convert this AC induction motor into a permanent magnet generator. This was going to be done by stripping the motor down and replacing the wound rotor with recyclable magnets. This looked like an attractive option since recyclable magnets with any shape can be used in the generator to explore its performance The author was unable to complete investigating this option in detail. This is strongly recommended for further work most probably at MSc level. 6.4 Challenges faced during the construction of the PM generatorThe main challenge in the construction of this wind generator was cost. For the laboratory investigation of the PM generator, a lot of materials, like the magnets and coils on the stator were found to be very expensive. This inadvertently gives more support for the use of recycled materials. There was a lot of machining needed for this project, the rotor and the stator needed to be cut and shaped to the desired diameter and drilled in the centre to fit on the mount structure. Time was the major constrained since a lot of things were required to be done in the limited time given for this thesis. However the framework of how to proceed in constructing and assembling the wind generator is already well laid out in this thesis. Chapter 7. Conclusions Based on the findings of the report, the following analyses and conclusions were drawn: 7.1 There is an urgent need of electricityDue to the number of people living without electricity in rural South Africa it is clear that alternative means of supplying these areas is essential. According to ESKOM, all house holds will eventually be electrified, but the problem is, what is happening in the meantime? Where are children’s medicines being stored? Therefore this makes the electrification process extremely urgent. 7.2 Resource assessment7.2.1Recyclable materials in the villageAn extensive assessment on the rural village of Ga-Rampuru was conducted. There are plenty of recyclable materials including old milling machines that are not in use. These materials can be recycled to clean Ga-Rampuru village. 7.2.2 Rural artisans who can assemble the wind turbineSince there are many local artisans who fix cars, electrical appliances and do some mechanical work in this village, manpower should not a problem. An engineer from the government or Non-governmental organization could educate these local artisans on assembling the wind generator. This will have a positive impact on Ga-Rampuru village as it will encourage people to work and be creative. There are many old wind mills used for pumping water in Ga-Rampuru village, most of these wind mills are working perfectly well supplying sufficient water. This is a clear indication that there is a reliable supply of wind in the village. 7.3 Simulation resultsIt has been shown that a reasonable amount of power can be realised from a generator using recycled magnets from the dumpsites 7.4 Cost involved in the designThe overall cost of assembling this wind generator system will be very cost effective since all the materials are recycled from the village, and the entire system will be assembled by local artisans. 7.5 Validity of this thesisSmall power that can turn on small lamps will really be appreciated in this village as children will be able to study after sunset. This will clearly have a wide range of positive developmental benefits on this community. Chapter 8. Recommendations Based on the above conclusions, the following recommendations were drawn: 1. For a more accurate recyclable wind turbine design, all its components such as the drum, the tower, rotor disk and cables must be explored in depth. The following must be considered: · Investigate how to extract maximum power from the wind using the drum, and how to prevent the drum from over spinning. · How to use other irregular recyclable magnets in the village in the generator design. 2. Investigate how a permanent magnet generator topology can be changed or re-designed to accommodate the design of a generator with the shape of the loudspeaker magnets. 3. Look in to how the magnets can be removed from the speakers, since very strong clue is used to mount them, how this can be done in a cost effective way. 4. The axial flux permanent magnet topology should also be looked into to compare it to the radial flux type. 5. The exact costs of assembling and maintaining the recycled wind turbine should also be incorporated in the design procedure. 6. With the little output power generated in this thesis, this project must definitely be taken further to alleviate the electricity problems in South Africa. References 1. Socio-economic rights project, “The right to affordable electricity” copyright @ community law centre 2002 2. IDASA, http://www.idasa.org.za 3. Department of Minerals and Energy, White Paper on the Renewable Energy Policy of the Republic of South Africa. August 2002 5. Sathyajith Mathew, “Wind Energy-Fundamentals, Resource Analysis and Economics ” © Springer- Verlag Berlin Heidelberg 2006 6. Smail Khennas, Simon Dunnett and Hugh Piggott, “Small wind systems for rural energy services”. ITDG Publishing 2003 7. Kevin Reeves, “The design and Implementation of a 6kW wind turbine simulator” University Of Cape Town, South Africa, Oct 2004 8. FrequentlyAskedQuestions http://www.magnetsales.com/Design/FAQs_frames/FAQs_2.htm © 2000 Magnet Sales & Manufacturing Company, Inc 9. R.C. Bansal, T.S. Bhatti, D.P. Kothari, “On some of the design aspect of wind energy conversion systems” Birla Institute of technology and science, Pilani, September 2002 10. Jacek F. Gieras, Mitchell Wing, “Permanent magnet motor technology-Design and Applications” 1st edition. Marcei Dekker, Inc. 1997 11. Prof E. J. Odendal, “Design, construction and testing of a small wind generator with electronic controller for domestic use”. University of Natal, Durban 12. Jacek F. Gieras, Mitchell Wing, “Permanent magnet motor technology-Design and Applications” 2nd edition. Marcei Dekker, Inc. 1997 13. P.C. Sen, “Principles of electric machines and power electronics” 2nd edition. John Wiley & Sons 14. Bhag S. Guru, Huseyin R. Hiziroglu, “Electric Machinery and Transformers” 3rd edition. Oxford University Press, Inc. 2001 15. Dr. James Livingston, “Magnetic Materials Overview” 16. E. Muljadi, C.P. Butterfield, Yih-Huei Wan, “Axial flux, Modulator, Permanent-Magnet with a Toroidal winding for wind turbine applications”. Cole Boulevard, Nov 1998 17. Magfag, 2003 by Force Field 18. M.A. Khan, P. Pillay, “Design of a PM wind generator, optimised for energy capture over a wide operating range” 19. Joe Naylor, “Speakers with Alnico magnets vs. speakers with ceramic magnets” 20. Hybrid (Wind/Solar/LP Gas) Systems for Rural Community Development, “Electrifying South Africa for prosperity and development”. Upper Maphaphethe by Mike Wintherden 21. Danish Wind Industry Association, ‘Guided Tour’ online htt://windpower.org/en/tour/wres/betz.htm 22. Lysen, E.H., ‘Introduction to Wind Energy’ CWD,2nd edition, p.p 51-73 23. Ripinga Nonkululeko, “Comparison of grid and off-grid rural electrification, based on the actual installation in Limpopo Province”. University of Cape Town, Oct. 2005 24. Alfred Still & Charles S. Siskind, “Elements of electrical machine design”. 3rd edition. McGraw-Hill Book company,inc. 1954 Appendix A Graphs of output rms induced voltage and flux of the generator 1. Commercial Standard Magnets a) Ceramic FLux_RMS = 0.0175 EMF_RMS = 3.6075

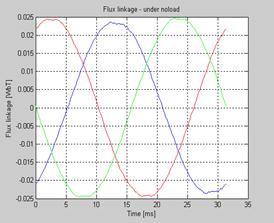

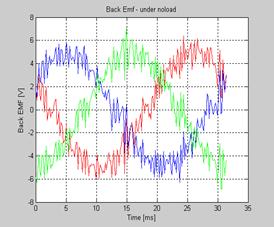

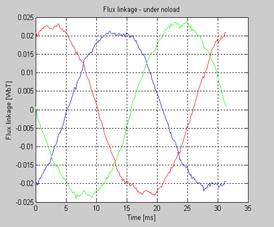

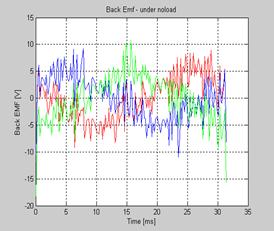

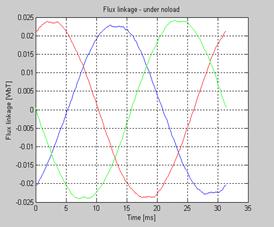

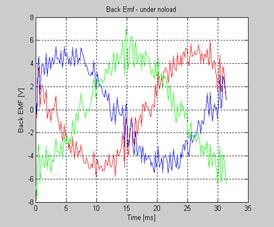

b) Alnico FLux_RMS =0.0168 EMF_RMS = 5.1619

c) NdFeB FLux_RMS = 0.0459 EMF_RMS = 9.4262

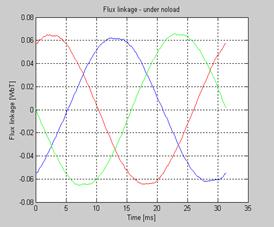

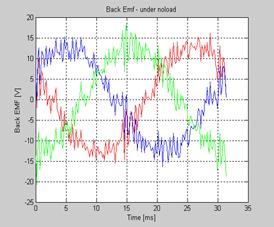

2. Loud Speaker Magnet FLux_RMS = 0.0171 EMF_RMS = 3.4987

Appendix B Matlab code for sketching the output emf and flux of the generators % EMF calculation from FEMM %By Maribini Manyage clc clear all; close all; P = 2; w = 1912; %mechanical speed in rpm freq = (w*pi/30)*P/(4*pi); %frequency XA = load('flux_link_A.txt'); XB = load('flux_link_B.txt'); XC = load('flux_link_C.txt'); beta = XA(:,1); % angle between Is_r and d-axis [elec degrees] alpha = beta - beta(1,1); % Rotor position in [elec degrees] from Zero time = alpha*(pi/180)/(2*pi*freq);%*1000; %time flux_link_A = 2*XA(:,2); flux_link_B = 2*XB(:,2); flux_link_C = 2*XC(:,2); % Perform spline in order to differentiate flux linkage vs time pp_flux_A = spline(time,flux_link_A); pp_flux_B = spline(time,flux_link_B); pp_flux_C = spline(time,flux_link_C); % extracting piecewise polynomial coefficients and derivation [hgt,wdth] = size(pp_flux_A.coefs); clear AA; for k = 1:hgt AA(k,:) = polyder(pp_flux_A.coefs(k,:)); end dpp_flux_A = MKPP(time,AA) [hgt,wdth] = size(pp_flux_B.coefs); clear AA; for k = 1:hgt AA(k,:) = polyder(pp_flux_B.coefs(k,:)); end dpp_flux_B = MKPP(time,AA); [hgt,wdth] = size(pp_flux_C.coefs); clear AA; for k = 1:hgt AA(k,:) = polyder(pp_flux_C.coefs(k,:)); end dpp_flux_C = MKPP(time,AA); %back emf emf_A = ppval(time,dpp_flux_A); emf_B = ppval(time,dpp_flux_B); emf_C = ppval(time,dpp_flux_C); figure(1); plot(time*1000,flux_link_A,'r-'); hold on; plot(time*1000, flux_link_B,'b-'); plot(time*1000, flux_link_C,'g-'); title('Flux linkage - under noload'); xlabel('Time [ms]'),ylabel('Flux linkage [WbT]') grid; figure(2); plot(time*1000,emf_A,'r-'); hold on; plot(time*1000, emf_B,'b-'); plot(time*1000, emf_C,'g-'); title('Back Emf - under noload'); xlabel('Time [ms]'),ylabel('Back EMF [V]') grid; x = length(flux_link_A); FLux_RMS = norm(flux_link_A)/sqrt(x) y = length(emf_A); EMF_RMS = norm(emf_A)/sqrt(y) |

(Eq.

3.7)

(Eq.

3.7)